‘Enabling’ Tech Drives Automotive Fastener Innovations

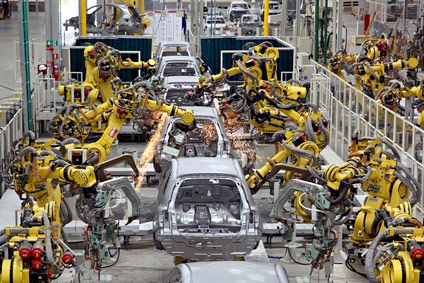

Technology advances related to automotive fasteners are generally a response to technology changes in the industries they impact, according to Fastener Training Institute instructor Laurence Claus.

“New automotive fastener technology is almost all entirely a function of being ‘enabling technology’ for recent advancements and needs in the automotive industry,” Claus told GlobalFastenerNews.com.

“New automotive fastener technology is almost all entirely a function of being ‘enabling technology’ for recent advancements and needs in the automotive industry,” Claus told GlobalFastenerNews.com.

Almost all of these advancements are centered around today’s automotive industry efforts to “lightweight,” or reduce the weight of parts.

Interesting new technologies include fasteners that enable “flow drill screwing” for one-sided access connections of thin sheet joining (especially aluminum to aluminum), self-piercing rivets for two-sided access connections of thin sheet joining (again, especially aluminum to aluminum), FEW technology (Friction Element Welding) for two sided access assembly of mixed material joints, particularly aluminum to high-strength and ultra-high-strength steel (probably the most interesting and revolutionary of all the new automotive fastening technology), self-piercing and thread forming fasteners for thermoplastic carbon-fiber reinforced materials, high strength aluminum fasteners, mostly for powertrain applications, and ultra-high strength, Austempered steel fasteners.

“Additionally, although not really “new” technology, there have been recent advancements in coatings that act as a di-electric to protect against galvanic corrosion of dissimilar materials in fastened joints and a continuing maturation of thread forming technology and practice, particularly in thermoplastic, thermoset, and light metal applications,” Claus added.

Salim Brahimi, Director of Engineering Technology at the Industrial Fasteners Institute, said automakers are reducing weight and improving fuel efficiency by pushing the limits of high strength steels.

“Some European manufacturers have implemented fasteners as high as 1600 MPa using martensitic and/or bainitic steels.”

For the full story, FIN subscribers can CLICK HERE.

There are no comments at the moment, do you want to add one?

Write a comment