Alcoa to Supply 3D-Printed Metal Parts for Airbus

The following is a press release provided to GlobalFastenerNews.com. Contact the individual company for additional information.

Lightweight metals leader Alcoa (NYSE:AA) has entered into an agreement with Airbus to supply 3D-printed titanium fuselage and engine pylon components for Airbus commercial aircraft. Alcoa expects to deliver the first additive manufactured parts to Airbus in mid-2016.

“We are proud to partner with Airbus to help pave the way to the future of aerospace development and manufacturing,” said Alcoa Chairman and Chief Executive Officer Klaus Kleinfeld. “The unique combination of our multi-material alloy development expertise, powder production capabilities, aerospace manufacturing strength and product qualification know-how position us to lead in this exciting, emerging space.”

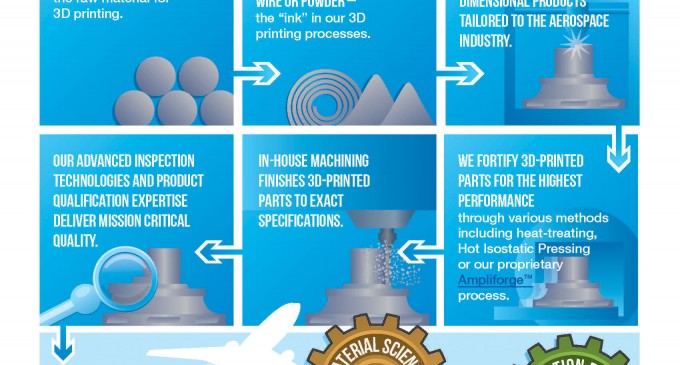

Airbus chose to work with Alcoa because of its comprehensive capabilities, from materials science leadership to additive manufacturing and aerospace parts qualification. The agreement will draw on Alcoa’s decades of aerospace experience and new technologies gained through the recent acquisition of RTI and organic expansion in Whitehall, Michigan. Alcoa also recently invested in 3D-printing and metallic powder production capabilities at its technical center outside of Pittsburgh, Pennsylvania.

- Last year, Alcoa acquired RTI International Metals (RTI)—now known as Alcoa Titanium & Engineered Products (ATEP)—which grew Alcoa’s additive manufacturing capabilities to include 3D-printed titanium and specialty metals parts produced at ATEP’s Austin, Texas facility. The Airbus agreement will draw on these capabilities as well as ATEP’s titanium ingot melting and billetizing, machining, finishing and inspection technologies.

- Alcoa will employ advanced CT scan and Hot Isostatic Pressing (HIP) capabilities at its advanced aerospace facility in Whitehall, Michigan. HIP is a technology that strengthens the metallic structures of traditional and additive manufactured parts made of titanium and nickel based superalloys. Through a $22 million investment in the technology in Whitehall, Michigan, Alcoa today owns and operates one of the largest aerospace HIP technology complexes in the world.

- Additionally, Alcoa is bolstering its additive manufacturing capabilities through a $60 million expansion in advanced 3D-printing materials and processes, including metallic powders. The expansion is located at the Alcoa Technical Center near Pittsburgh, Pennsylvania, the world’s largest light metals research center.

Details of this agreement with Airbus were not disclosed.

Alcoa Aerospace

Alcoa’s aerospace businesses will form part of the Value-Add Company, to be named Arconic, following Alcoa’s separation in the second half of 2016. Arconic will be a premier innovator of high performance multi-material products and solutions in attractive growth markets, including aerospace. This agreement is Alcoa’s latest with Airbus, building on last year’s fastening systems agreement valued at approximately $1 billion. That deal was Alcoa’s largest fastener contract ever with the aircraft manufacturer. Alcoa’s fasteners fly on every Airbus platform.

About Alcoa

A global leader in lightweight metals technology, engineering and manufacturing, Alcoa innovates multi-material solutions that advance our world. Our technologies enhance transportation, from automotive and commercial transport to air and space travel, and improve industrial and consumer electronics products. We enable smart buildings, sustainable food and beverage packaging, high-performance defense vehicles across air, land and sea, deeper oil and gas drilling and more efficient power generation. We pioneered the aluminum industry over 125 years ago, and today, our more than 60,000 people in 30 countries deliver value-add products made of titanium, nickel and aluminum, and produce best-in-class bauxite, alumina and primary aluminum products. For more information, visit www.alcoa.com, follow @Alcoa on Twitter at www.twitter.com/Alcoa and follow us on Facebook at www.facebook.com/Alcoa.

In the second half of 2016, Alcoa will separate into two industry-leading, Fortune 500 companies. The innovation and technology-driven Value-Add Company will include Global Rolled Products, Engineered Products and Solutions, and Transportation and Construction Solutions. The globally competitive Upstream Company will comprise five strong business units that today make up Global Primary Products—Bauxite, Alumina, Aluminum, Cast Products and Energy.

There are no comments at the moment, do you want to add one?

Write a comment