Implant Relies on Unique Fastener to Gear Up for Baby Boomer Generation

PRODUCT NEWS

Implant Relies on Unique Fastener to Gear Up for Baby Boomer Generation

By Del Williams

To handle active baby boomers and rising longevity, Skeletal Dynamics specifies an innovative self locking fastener that withstands up to one-million loading cycles for its new elbow replacement implant.

As the first of the baby boomer generation turns 65 this year and promises to live longer and more actively than previous generations, implants and their components-including the fasteners that hold them together-must be built to last longer than ever before.

To handle the demands of tomorrow’s dynamic baby boomer population, for whom jogging, tennis, and golf have been generational pursuits, some medical device companies are going beyond what’s currently required. For instance, some are specifying self locking fasteners in implants of the upper extremities that go way beyond 100,000 load cycles to withstand up to one-million load cycles without loosening or backing out.

“Patients are living longer and more vigorously than past generations, and that’s only going to increase as baby boomers demand more from their muscular-skeletal systems well past traditional ‘retirement age,'” says Tom Norman, Vice President of Engineering at Miami, Fla.-based Skeletal Dynamics, a designer and marketer of innovative orthopedic devices.

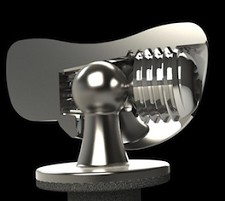

To keep up with active baby boomers, Skeletal Dynamics recently developed its Align™ Radial Head System, an artificial elbow joint designed to restore the natural function of the native radial head.

Previously, prosthetic radial head designs typically followed one of two approaches with significant drawbacks. While a traditional fixed monoblock design offered stability, it could not be aligned to the patient’s anatomy, which tended to wear away natural tissue such as cartilage. A bi-polar radial head was an attempt to align with the patient’s native anatomy, as it was able to rotate in a polyethylene sheath, but would not remain in the correct position because it would not lock.

“We aimed to fill a gap in the market by providing the ability to orient the joint to its natural position during surgery, and then locking it in place for the rest of the patient’s life,” says Norman. “We considered traditional fastener thread forms, but lacked confidence that they would stay in place for the up to a million load cycles an active patient could subject them to in their lifetime. Instead, we selected an innovative self locking fastener called Spiralock.”

Because repetitive loads, shock and loosening must be decisively handled for implant use, traditional fasteners susceptible to self-loosening rotational movement, stripping, and shearing are not always appropriate. Testing, in fact, has found that the first two threads of traditional fasteners can carry as much as 80% of the load, permitting stripping or shearing, while subsequent male threads “float” within the female threads.

Medical device manufacturers such as Skeletal Dynamics are successfully attacking these problems with a variety of new technologies. One of the most interesting solutions is also the simplest-an innovative self locking fastener called Spiralock. By its unique design, it is capable of resisting loosening even under loads and vibrations strong enough to break the fastener.

What makes Spiralock unique is its 30º “wedge” ramp cut at the root of the female thread (while traditional fasteners use a 60º thread). Under clamp load, the crests of the threads on any standard male bolt are drawn tightly against the wedge ramp. This not only eliminates sideways motion that causes vibrational loosening but also distributes the threaded joint’s load throughout all engaged threads, a claim supported by a Massachusetts Institute of Technology research study. The load percentage on the first engaged thread is significantly lower than traditional thread forms, which further reduces possible bolt failure and improves product performance.

In the medical field, because of their vibration-resistant, reliable self locking features, the innovative fasteners hold various components together in implants, artificial limbs, heart pumps and MRI machines, and are also being considered for cardiovascular devices such as pacemakers and implantable defibrillators, as well as for dental and orthopedic surgical instruments and CT scanning applications.

When Skeletal Dynamics’ Align™ Radial Head System is surgically installed in a patient, proprietary instrumentation allows alignment of the radial head as it would be in the patient’s native anatomy. Once the surgeon orients the device in this natural position, the surgeon tightens the set screw in a Spiralock milled interrupted thread made of cobalt chrome, against a long titanium stem designed for 3-point fixation, to lock the device in the correct position.

“While fasteners used in upper extremities are frequently tested to 100,000 cycles, third-party testing showed that the Spiralock self locking fastener used on the Align™ Radial Head successfully survived load and fatigue testing to one-million cycles without loosening or backing out,” says Norman. “That gave us the design confidence we needed, and helped with our FDA approval.”

Early in the design process, when Skeletal Dynamics considered the manufacturability of the self locking thread, Spiralock Corp. stepped forward to manufacture prototype tooling for them, then customized tools to cut the thread form, and finally worked closely with their contract manufacturer to scale up production. “We were happily surprised at the cost of the self locking fastener, and are considering its use in other medical applications,” says Norman.

“Going right to the Spiralock self locking fasteners, to address fastener fatigue and loosening, potentially saved us millions of dollars and years of development time,” concludes Norman. “For fastening challenges in the medical industry, like designing for active baby boomers and rising longevity, the sooner they’re considered the better.”

Spiralock, whose self locking fasteners are used for design challenges in a wide range of industries including medical, aerospace/military, automotive, heavy truck, food processing, agriculture, construction, rail, and oil drilling is part of Emhart Teknologies, known for total vehicle innovation in the auto industry. The self locking Spiralock fasteners have been used in extreme fastening applications with virtually no chance of recall: from the main engines of NASA’s Space Shuttle; to the Saturn Cassini orbiter and Titan Huygens probe; to medical implants, artificial limbs, and heart pumps.

For detailed test data, including comparative graphic loading characteristics or photoelastic analysis/load vector comparison animation, visit Spiralock at www.spiralock.com; email slinfo@spiralock.com; call (800) 521-2688; fax (248) 543-1403; or write to Spiralock at 25235 Dequindre Rd, Madison Heights, MI 48071. For information on Emhart Teknologies, please visit www.emhart.com

###

Del Williams is a technical writer based in Torrance, California.

There are no comments at the moment, do you want to add one?

Write a comment