1998 FIN – The Ubiquitous A325

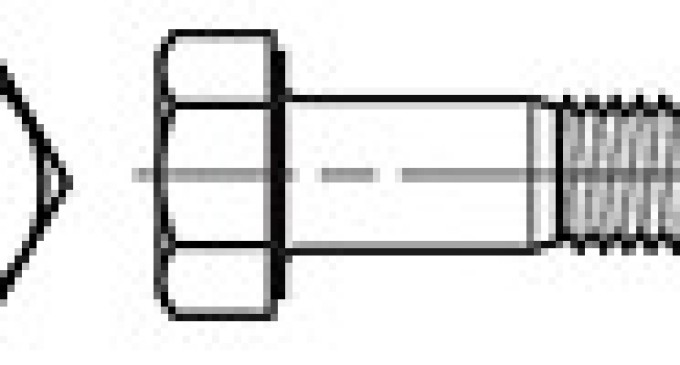

A325 (photo courtesy of Industrial Fasteners Institute).

2015 FIN ? ASTM Consolidates Structural Fastener Specifications

2015 FIN – The ASTM Committee F16 on Fasteners has consolidated six structural fastener standards into ASTM F3125. The new standard covers structural fasteners for holding steel structures together from high-rise construction to retail to airport terminals to sports facilities.

ASTM touted the new “streamlined approach” with one standard: F3125 Specification for High Strength Structural Bolts, Steel & Alloy Steel, Heat Treated, 120 ski (830 MPa) and 150 ski (1040MPa) Minimum Tensile Strength, Inch and Metric Dimensions.

With hundreds of millions of fasteners manufactured to ASTM specifications annually,

“This is an example of what can happen when fresh perspectives, cooperation and effort combine,” said subcommittee chair Chad Larson of LeJeune Bolt Co. “The new standard maintains virtually all of the previous technical requirements and ads much needed changes in a very efficient manner.”

The six standards consolidated into ASTM F3125 are: ASTM A325 and A325M for steel heat-treated structural bolts; ASTM A490 and A490M for steel alloy heat-treated structural bolts; and ASTM F1852 and F2280 for “twist off” type tension control structural bolt/nut/washer assemblies.

The F16 committee worked with the American Institute of Steel Construction and Research Council on Structural Connections

With hundreds of millions of fasteners manufactured to ASTM specifications annually, fastener manufacturers, structural engineers and steel construction agencies will benefit from the streamlined standard, according to ASTM.

Copies of the new standard are available online: astm.org Email: sales@astm.org

©2015 Fastener Industry News.

October 29, 1998 FIN – Editor’s Note: The American Society for Testing Materials is marking its 100th anniversary by highlighting its most important standards in a “Heritage Collection.” The ASTM Committee F-16 on fasteners chose ASTM Standard A325 for structural steel bolts for the collection. The following are excerpts from a Standardization News article on the bolt:

“Every steel building being erected in North America utilizes A325s,” Gene Mitchell, producer vice chair of ASTM Committee F-16 on Fasteners, described the importance of the bolt.

“In the late 1940s fastener producers began to manufacture heavy hex head, high-strength bolts suitable for critical applications such as building and bridge construction,” Maryann Gorman wrote in Standardization News. “It quickly became apparent, as it usually does, that an industry-wide standard was necessary to ensure the quality of these crucial connectors.”

ASTM developed A325 specifying the chemical composition and mechanical properties plus testing and inspection requirements for quenched and tempered structural steel bolts.

The standard “has become an integral part of every steel structure built in the United States, Canada and often in other countries, since the 1950s,” the publication reported.

In addition for use in construction, the flexibility of the A325 makes it useable in heavy equipment and other applications.

Jim Schiele of St. Louis Screw & Bolt recalled the development of the heavy hex head, high-strength bolt and the subsequent testing the fasteners went through at three university research sites in the mid-1950s.

“It’s a real tribute to the standard that since the heavy hex head, high strength bolt was introduced along with the standard in the early 1960s there has not been a single known bridge failure due to bolt failure,” Schiele told Standardization News.

Schiele added that adhering to the standard “has helped make St. Louis Screw & Bolt a better company.”

Committee F-16 shares much of its membership with the Research Council on Structural Connections, the Industrial Fasteners Institute, the American Institute of Steel Construction and the Bolting Technology Council.

Mitchell said revising the minimum tensile strength requirement is the next major change for the committee. Updating the 105 ksi figure would utilize the existing heat treatment technology and bring the requirements for these large A325 bolts in line with ASTM A 490.

“During the ’50s and ’60s, the consistent and uniform through-hardening of large diameter structural bolts was extremely difficult. Today, with the advances in heat treatment technology, the through-hardening process is not the dilemma it once was,” Mitchell added.

Gorman concluded that technology improvements “have provided humans with unprecedented safety in their built environment, and much of this safety is due to the work of committees like F-16 on Fasteners. The next time you drive safely over a sturdy bridge or walk unthinking into your high-rise office building, remember the ubiquitous A325 bolt.” ©1998/2009 Fastener Industry News

For information on permission to reuse or reprint this article please e-mail: FIN@GlobalFastenerNews.com

Related Links:

• ASTM

There are no comments at the moment, do you want to add one?

Write a comment