E-mobility Puts Pressure on Fastener Processing

The following is a press release provided to GlobalFastenerNews.com. Contact the individual company for additional information.

A million electric cars on Germany’s roads by 2020. This is the ambitious target set by the Federal Government in its bid to continue the battle against climate-destroying CO2 emissions. It believes that e-mobility is a significant key technology to create a sustainable transport system for the future,  especially where the power is produced from renewable energy sources. Yet e-mobility is still in its infancy: it is estimated that there are only around 1500 electrically powered vehicles on our roads today. That is why all those involved – policy-makers, industrialists and scientists – are working flat out to resolve all the outstanding issues. A great deal more research and development work is required before electric cars are fully ready for the market and before consumers will accept them.

especially where the power is produced from renewable energy sources. Yet e-mobility is still in its infancy: it is estimated that there are only around 1500 electrically powered vehicles on our roads today. That is why all those involved – policy-makers, industrialists and scientists – are working flat out to resolve all the outstanding issues. A great deal more research and development work is required before electric cars are fully ready for the market and before consumers will accept them.

Lithium ion batteries replace the fuel tank in an electric car. Intensive research is under way to improve these. In a statement, industry policy-makers said: “Our aim is to reduce the cost of the batteries since it is the battery that continues to be the most expensive component inside an electric car.” The Ministry of Transport requires that the energy density of batteries – i.e. the charging capacity measured against the volume – be increased even further. At present a battery stores much less energy than is produced by a full tank of petrol or diesel. This means that an electric car has a much shorter range than a car with a combustion engine.

The automotive industry and its suppliers are in a catch 22 situation. The government requires them to get e-mobility on the road as fast as possible, but they have to keep an eye on the competition as they do so. Due to the current low numbers of electric cars, assembling them on the customary fully-automated assembly lines would seem unprofitable. Jürgen Hierold, Sales Manager at engineering company DEPRAG SCHULZ GMBH u. CO. based in Amberg, Germany, explains the problems: “This industrial sector of the future is faced with a dichotomy in planning its assembly systems. Any technology selected today needs to be adaptable and flexible, so that as numbers grow it can be turned into a fully automated plant. Moreover, assembly work carried out now in small numbers has to be to the utmost precision since – as is the case with all automotive assembly – an assembly fault can prove to be fatal.

Assembly lines with intelligent manual stations are the most efficient solution to meet this requirement. Plant engineers DEPRAG designed and built an assembly line for a renowned automotive supplier in just six weeks – from receiving the order to delivering the first units. Power controllers for use in electric cars are assembled on some 40 manual workstations. Jürgen Hierold: “This is where the “brains” of future electric cars are safely and reliably fastened together by means of several hundred screws. DEPRAG, a full service supplier, won the order because it was able to meet all the technical requirements from a single source.

Jürgen Hierold: “Our customer viewed this order as particularly complex because it needed to cover all the various requirements of the assembly process”. The main requirements were to ensure and maintain maximum processing reliability for these safety-critical components. Furthermore, a high level of flexibility was also required to deal with the wide range of variants. The sensitive electronic components require that the parts used to build them possess reliable electro-static discharge capabilities (ESD-capacity). In addition, these components require an assembly environment that reliably meets technical cleanliness guidelines. It goes without saying that the manual workstations have to be ergonomically designed. Jürgen Hierold: “Using our standard components and solutions, we were able to provide an efficient solution to what the customer had believed would be a difficult problem. All the components had already been coordinated and harmonised with one another. We are able to avoid the major friction, losses and delays which always occur when customers have to purchase components from different sources and then coordinate and harmonise them all.

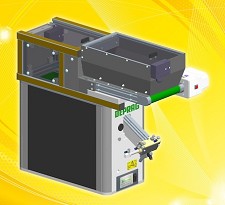

All the components, such as the sensor-controlled screwdrivers, feeder systems, position control portals, control and analysis electronics, tool-change monitoring systems, pick-and-place units etc., come from the company’s standard range.

The yardstick for processing reliability of bolted connections is particularly stringent in the automotive industry (VDI standard 2862, category A). Every step of the assembly process has to be monitored and recorded. So how is this achieved at a manual workstation? DEPRAG designed a high-quality steel profile position-monitoring portal to ensure that the EC-servo screwdriver is guided into the correct vertical direction. The portal provides a high level of accuracy in controlling the screw fastening process. Jürgen Hierold: “The assembly worker is at his workstation using our MINIMAT®EC-Servo screwdriver system to carry out his screw-driving tasks. The new position-control portal guides him step-by-step through the job. At each screw position the sensor technology activates the fastening parameters, releases the fastener, indicates if a bit change is required for the screw position, monitors the screw fastening and analyses the results.

The work surface can be height-adjusted, thus allowing workers to sit or stand as they wish.

The different fasteners are fed through the sword feeder directly into the screwdriver or into a “receiver” from which the screws can be picked. The entire assembly line ultimately comprises over 60 feed devices. Jürgen Hierold: “For this assembly facility we are deploying feeder technology that meets every criterion of what is known as technical cleanliness. It differs from a vibratory feeder in that there is no vibration, and fasteners are subject to very little abrasion as they are conveyed. Moreover there are vacuum connections at every point where abrasion could occur. Any harmful contaminating particles are simply sucked away.” And changing the bit, necessary when changing from one screw size to another, takes no longer than the blink of an eye. A tool box with intelligent quick-change equipment and vacuum guide sleeve ensures that workers can change the bit quickly and easily. ESD capacity over the complete line has also been taken into consideration.

DEPRAG is well known for its user-friendly and intuitive control and measurement technology to control and record the assembly processes. Every workstation on the new assembly line for fastening together electric car control units has its own IPC-based process controller. Sales Manager Mr. Hierold said: “Our DCOS software, developed in-house and proven a hundred times over, “recognises” the different sizes and types of screw, the screw parameter configuration and the tightening procedure to be used, as well as the correct insertion tool for each position. The sequence for making the screw connection is also precisely configured. Whatever the job – a torque/angle-controlled tightening procedure, a friction coefficient procedure or a special tightening procedure – workers can use the clear and easy-to-read touch screen to record whether the screwdriving job has been carried out satisfactorily.

It’s not just the control and measurement technology that ensures good interplay between man and machine (HMI). The MINIMAT®EC-servomotor screwdriver with its tried-and-tested sensor-controlled technology gives workers the option to start the screwdriver by pressing a button or a key on the keyboard. The ball-bearing at the position control portal and the reduced mass make the screwdriver extremely light and agile in use. So worker fatigue is reduced to a minimum. The ergonomically adapted screwdriver handle also helps to combat tiredness. Likewise, the ability of the DCOS control system to visualise the screwdriving job makes a huge contribution to optimum worker guidance on the entire system.

Ultimately, all the requirements that needed to be in place to assemble the power controllers – processing reliability, flexibility, ESD capability, technical cleanliness, ergonomic design and cost effectiveness – have been achieved using DEPRAG standard components, and to the customer’s fullest satisfaction.

While the progress of e-mobility and the expected numbers of electric cars which will be produced in the future remains unclear, one thing is certain: As time goes on, DEPRAG customers will be able to make use of many components of the assembly lines they acquire now, when – as is the intention – more electric cars are in circulation on our roads. DEPRAG’s product manager, Dagmar Dübbelde, said: “We can handle the anticipated rise in numbers. Besides our expertise in the fields of screwdriving technology, feed technology, control and measurement technology, we are also the right partner for automation. Our in-house plant engineers are able to include elements of the existing assembly line into an automated line. The investment pays for itself.”

For several decades DEPRAG SCHULZ GMBH u. Co. has been closely concerned with automation solutions. With over 600 employees in more than 50 countries, not only is DEPRAG an expert full-service provider in technologies encompassing screw fastening, feeders, control and measurement, DEPRAG standards components also combine to form complete, fully or partially automated assembly facilities. DEPRAG is a single source supplier – from the initial consultation through to the after-sales and maintenance service – offering an unrivalled range of services.

Related Stories:

• Hillman To Acquire H. Paulin & Co.

There are no comments at the moment, do you want to add one?

Write a comment