Rivet Nuts Improve Production at GM Assembly Plant

Traditionally, operators at General Motors (Detroit) installed rivet nut fasteners into vehicle bodies with a handheld power screwdriver. Despite such a time-consuming process, General Motors decided to increase the number of fasteners on each side of the vehicle from four to five, according to Goebel Fasteners.

A fastener handling system solved the problem.

“The fastener handling system uses an escape-and-blow mechanism to deliver the fasteners to a receiver head, eliminating the most time-consuming part of the previous operation,” according to Goebel Fasteners.

“The fastener handling system uses an escape-and-blow mechanism to deliver the fasteners to a receiver head, eliminating the most time-consuming part of the previous operation,” according to Goebel Fasteners.

“The handling system also eliminated the costly problem of fasteners dropping on the floor. The system’s design includes a modular supply hopper, vibratory bowl feeder and an integrated electric-drive power screwdriver.”

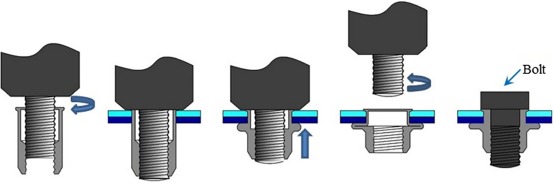

Rivet nut fasteners are internally threaded fasteners that can be installed in seconds by a single operator from one side of the work. When in place, they form secure nut plates with clean threads for screw attachments. The fasteners stay firmly anchored, even when repeatedly assembled.

The style used on General Motor’s sport utility vehicles features thin-wall shanks that compress during installation, forming large flanges. These flanges spread loads evenly over a large area, providing strong pull-out resistance. Other benefits include wide grip range, and exceptional torque and thread strength.

Click here to read the full article.

There are no comments at the moment, do you want to add one?

Write a comment